About Multi-Wavelength MatchBox laser

The Multi-Wavelength MatchBox laser is a configurable turnkey emitter/detector system for life sciences, sorting, and particle analysis applications. It has a standard MatchBox footprint and is compatible with a rich set of MatchBox® accessories.

Features

- 2 to 4 individually controllable laser diode drivers

- Ultra-compact All-in-One design*

- Thermally stabilized optics

- Monolithic design for hands-free operation

- Fiber coupling and beam shaping options

- Automatic current control

- PD (power delivery) compatible USB-C power input (in breakout box)

Customization

- The desired set of 2 to 4 emitters/detectors

- Customer specified set of dichroic mirrors, clean-up and blocking filters

- Common output beam shaper, such as line generator, DOE, focusing optics, etc.

- Fiber end collimators and beam shapers

- Pre-programmed modulation patterns

- Customer specified beam diameter and divergence

- Customer specified fiber pigtail

- Amplifier circuits for avalanche photodiodes

Novel Product Concept

The multi-wavelength MatchBox® laser includes from 2 to 4 laser diode drivers and digital control electronics, which allows smart control and diagnostics of the complete module.

The laser unit is designed as an integration-ready electro-optics unit, which can be connected to a control mainboard and power supply of an instrument. This way the laser/detector unit provides unprecedented compactness and functionality. Thus mass production of multi-wavelength instruments becomes much easier and faster.

Communication protocol

MatchBox® series lasers feature a Universal Asynchronous Receiver/Transmitter (UART) controller interface. The pinout of MatchBox Combiner is an expanded version of the standard MatchBox® pin-out. The lower row of pins is the same as for single-wavelength lasers, while the second (upper) row is added for individual TTL modulation of each laser diode installed in the combiner.

Break-out-Box

A 'Break-out-Box' is used for converting UART into a USB protocol. The converter chip for USB is 'Silicon Labs CP2102'. Additionally, the break-out-box of the multi-wavelength MatchBox laser is equipped with the necessary circuit for communication and PD type (power delivery) power supplies.

Pins for Tight Integration

10 pins at the back of the laser combiner provide full access to the complete functionality of the combiner.

Pins are located at the backside of the enclosure and distributed in a way, which allows for implementing a mechanical reverse lock.

Prerequisites for such integration are a microcontroller mainboard supporting UART communication, 12V or 9V at 1.5 A (Power delivery) power supply, and 2 to 4 TTL channels for an individual on/off digital modulation (or fast PWM power control) of each laser diode.

Pin-out Explained

- L1 on/off diode TTL, 5V tolerant and 3.3V compatible

- L2 on/off diode TTL, 5V tolerant and 3.3V compatible

- GND ground connected to the laser body

- L3 on/off diode TTL, 5V tolerant and 3.3V compatible

- L4 on/off diode TTL, 5V tolerant and 3.3V compatible

- GND ground connected to the laser body

- Progr. pin is used to control fan of a heatsink, based on laser body temperature.

- Rx UART communication, 5V tolerant

- Tx UART communication, 5V tolerant

- Vcc 9-12V at 1.5 A, or PD (Power delivery) compliant power supply.Note: since the 3d of July 2020, the marking of Wavelength combiner pinout has changed, but all internal hardware is still the same.

Break-out-Box Explained

The Break-out-Box contains UART-USB converter circuit and conventional connection ports in a plastic housing.

- Data USB (left) is used for communication with a PC

- Interlock occupies two pins: INT-GND and INT. When the pins are shortened with an interlocking loop, the laser can be operated

- L0, L1, L2, L3 are all digital TTL modulation pins for corresponding laser diode channels or read-out pins for photodetectors, depending on product configuration.

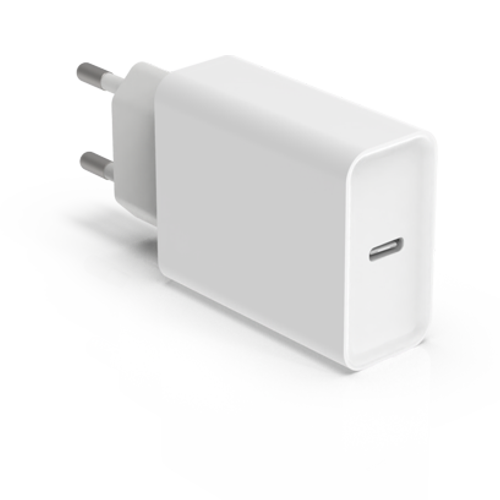

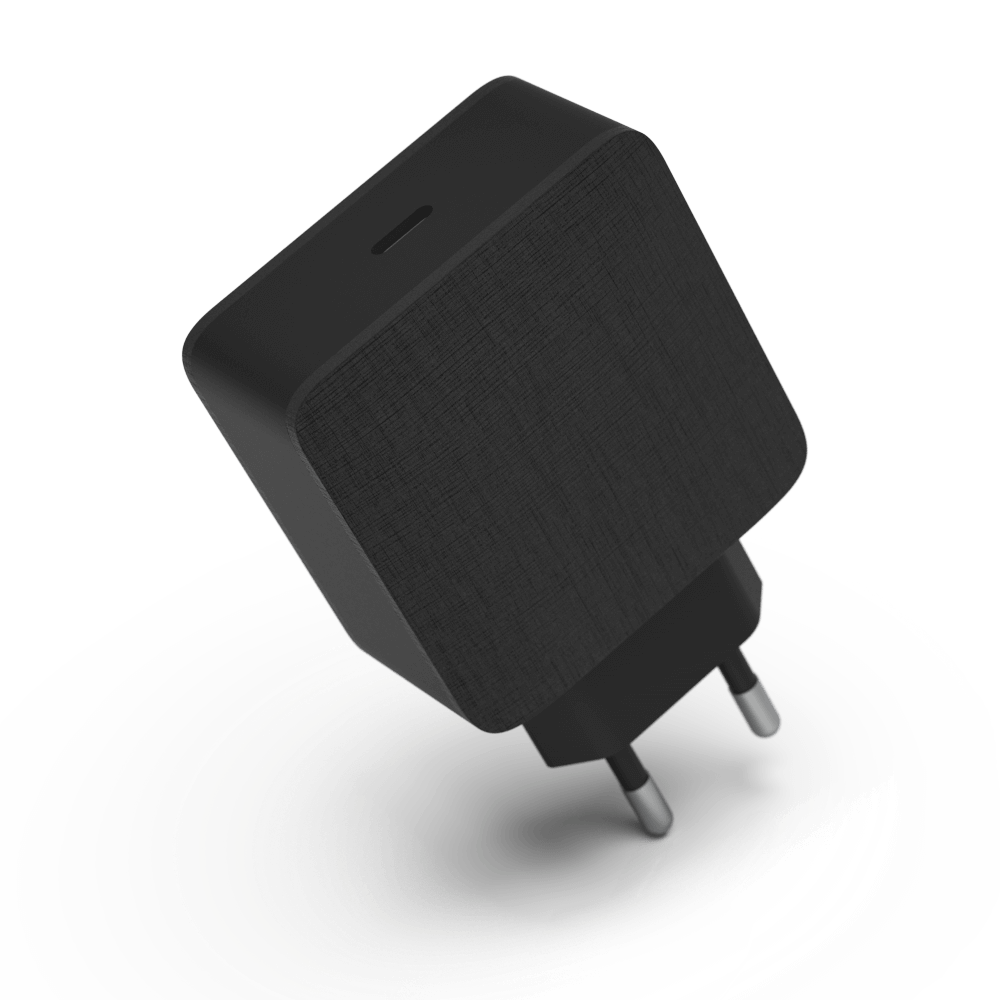

- Power input USB-C (right) connector is used for connection to a PD (power delivery) compatible power supply.

- Fan ctrl. connector (not visible, on the right side of the breakout box) is compatible with all our fan-based heatsinks.

Software Interface

The MatchBox® laser control software is used for checking preset parameters, such as the max. laser diode current, target temperatures for laser internal diode, laser body, and actual measured values of these parameters, as well as the load percentage of the Peltier elements.

This is very helpful for laser diode age tracking and other troubleshooting actions.

The MatchBox® laser control software is used for checking preset parameters, such as the max. laser diode current, target temperatures for laser internal diode, laser body, and actual measured values of these parameters, as well as the load percentage of the Peltier elements.

This is very helpful for laser diode age tracking and other troubleshooting actions. Heatsinks

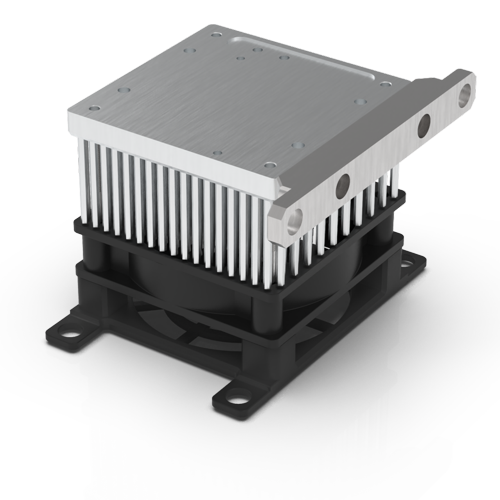

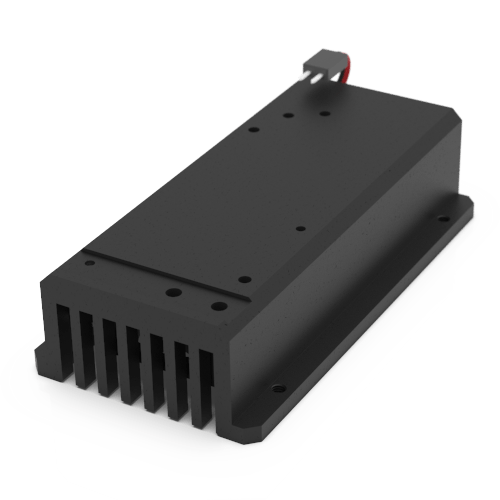

A low profile forced-air cooler has an integrated centrifugal fan. Very efficient for dissipation of excess heat.

A compact TEC-cooled mounting adapter plate is a great cooling unit for good thermal and mechanical stability requiring lasers and setups.

Power Supplies

Advantages

- Easy to integrate (smallest enclosure on the market)

- Convenient to arrange in the proximity of a working area (use of fiber pigtails is often not necessary)

- Standard Package (MatchBox®)

- User-friendly software with multiple parameter monitoring

- Low power consumption in standby-mode (important for battery-powered applications)

- Excellent beam pointing angle and beam position accuracy

- High cooling capacity

- Rugged enclosure

- Operational hours counter

- On/Off cycle counter

- Smart over-heat protection

- Power delivery (PD) based power supplies

- Variety of accessories

- Space-saving pinhead connector

What's in the Box?

- Laser Source (integrated power electronics in the same enclosure)

- One thermal film. If a laser is sent mounted on a heatsink with a thermal film, an additional 1 g of thermal grease is included.

- 2 screws of M2.5x20 mm for fixing the laser to a mounting plate. Tightening torque 0.25 - 0.35 N·m

- Hex key: 1.5 mm; BN:1169; DIN:911